Using performance-based logistics (PBL) for US defence contracts

The initiative

The 2001 Quadrennial Defense Review rejected the traditional model and committed the DoD to using performance-based logistics (PBL) for major weapon systems sustainment and commodities contracts. PBL was designed to “optimise system readiness and meet performance goals for a weapon system” [1] by taking a new approach to the contracts for how major weapons are maintained after they have been acquired.

The PBL initiative was “intended to create a ‘level playing field' where in-house or contracted organisations [would be] selected for logistics support of a given commodity or weapon system based on their performance rather than the nature of the source”. [2] The overall objective was to increase the readiness levels of systems by purchasing sustainment services through a comprehensive, more affordable package.

The 2001 Quadrennial Defense Review provided initial guidance and mandate for the use of PBLs. The DoD acted in the following ways:

- Provided guidance to the Military Services and agencies that contract out maintenance, establishing criteria for when PBL contracts should be used and when they should not.

- Published a guidebook and toolkit for program managers implementing PBL contracts.

- Created a PBL “Community of Practice” - an online community for PBL practitioners to collect and share best practices and lessons learned.

“PBL thus embodies a premise of military leadership called ‘commander's intent': present the vision, strategy, and goals, but encourage subordinates to choose their methods. Companies decided which best practices to adopt. Payment is based on performance, with incentives for time and cost-savings.” [3]

The challenge

It is estimated that over the lifecycle of a machine, 30 percent of money is spent on its acquisition and the remaining 70 percent on support.

Before 2001, the US federal government had experimented with performance-based contracting in a limited fashion. However, the Department of Defense (DoD) continued to rely on the traditional “spares and repairs” or transaction-based model for maintaining weapon systems. It would pay government depots or private contractors for their labour hours and the spare parts needed to maintain those systems.

The public impact

Equipment maintained under PBL arrangements experience better availability for mission-tasking, better reliability, and better maintainability than equipment repaired under transactional arrangements.

Properly structured and executed, PBLs reduce Military Services' cost per unit-of-performance while also increasing the readiness levels of weapon systems, subsystems, and components.

The average annual savings for programmes with generally sound adherence to PBL tenets is 5 to 20 percent over the life of the PBL arrangement compared to transactional support.

Stakeholder engagement

The roots of DoD's PBL effort date back to the Clinton Administration, with subsequent Republican and Democratic administrations supporting the concept.

The Defense Business Board - an independent board of private sector executives who advise the Secretary of Defense - recommended that DoD ‘pursue PBL aggressively' in their 2003 report; they consulted with industry stakeholders to compile best practices for DoD to implement.

The National Defense Industry Association (NDIA - the primary defense corporate advocacy organisation) came out in support of DoD's PBL efforts in 2002.

Political commitment

Frank Kendall, the under secretary of defense for acquisition, technology, & logistics, came out strongly in support of expanding the number of PBL contracts. "'This area will receive additional management attention,' he adds. 'We are going to increase the use of this business approach.'" [4]

The Heritage Foundation, a conservative think tank that is highly influential among Republican lawmakers, is a key proponent of PBLs.

Congress, however, has been lukewarm in its support, because PBLs could impact the number of jobs in military maintenance depots.

Public confidence

Although there is no direct information about the confidence of the public in the PBL initiative, US public confidence in the military is high. In 2001, 66 percent of citizens had a ‘great deal’ or ‘quite a lot’ of confidence in the military. In 2015 this had risen to 72 percent.Clarity of objectives

The DoD laid out explicit outcomes in numerous policy documents, including the ‘Performance Based Logistics Comprehensive Guidance Memorandum’ and the continually updated ‘PBL Guidebook: A Guide to Developing Performance-Based Arrangements’. These ensured that the objectives of using PBL, essentially cost-savings and greater efficiency, were maintained.Strength of evidence

Before 2001, the US federal government had used with performance-based contracting, although in a limited way. It was made part of DoD policy as a result of the 2001 Quadrennial Defense Review.

A 2006 study by the University of Maryland's Center for Public Policy and Private Enterprise demonstrated PBL's success in increasing readiness for specific platforms.

In 2011, the DoD commissioned a study by Deloitte to determine the impact of PBL on life cycle costs. The report summarises opinion about PBL as positive from a technical sense but equivocal about the cost-savings. "There is widespread (but not universal) agreement that equipment maintained under PBL arrangements experience better availability for mission tasking, better reliability, and better maintainability than equipment repaired under transactional arrangements. However, disagreement exists regarding the affordability of the improved performance." [5]

Feasibility

The DoD has recognised that there are barriers to PBL implementation and has worked to mitigate them (e.g., a lack of repeatable processes, tools, and lessons learned led to development of the PBL Best Practices Guidebook). It has recognised that PBLs are not always the best tool and has provided guidance as to when contracting officers should use PBLs and when they should not.

PBL has been implemented across each of the US military services and other organisations, such as the Defense Logistics Agency.

Management

Frank Kendall made PBL a key part of his signature comprehensive guidance for the acquisition community - Better Buying Power. The 2011 Deloitte Proof Point report was an extensive exercise to provide true evidence of impact and to provide recommendations for improving execution of PBLs.

The management structure for implementing PBLs is clearly defined. Product Support Managers (PSM) are responsible for determining the level of support required for a programme and for the “performance of the overall product support strategy”. [6] PSMs can delegate arrangements for one or more elements of a system to a Product Support Integrator (PSI). Responsibility for certain elements can also be delegated to Product Support Providers (PSP). “For example, if the PSP is responsible for performing training for an aircraft system, measuring the number or pilots qualified or maintainers certified per month would be an appropriate metric.” [7]

Often, management is shared between Defense Force personnel and private contractors, which requires a collaborative approach to management. “The depot and the contractor managers coordinate things effectively so that the depot managers can instruct their employees and contractor managers can instruct their employees in a way that avoids confusions, and I have been here for almost four years and have yet to run into a conflict in this area.” [8]

Measurement

The PBL Guidebook includes detailed instructions on how to set up outcome measurements (the "12-Step Standard and Repeatable Approach to PBL").

The 2011 Deloitte study collected extensive performance and financial data. It included "consistent and comparable data" from multiple military programmes to analyse and provide evidence of PBL impact. [9] It recommended developing a portfolio of agreed-upon KPIs. The DoD has developed guidance on developing metrics for PBL contractors.

Alignment

The DoD has developed a robust ‘PBL Community of Practice' to help distribute policy, guidance, lessons learned, and other resources across the personnel procuring and implementing PBL contracts.

PBL is intended to be a cooperative than a traditional transactional contracting of services. According to the DoD, PBL “aligns the interests of Industry and the Government, creating internal competition, motivating Industry to improve their product quality (reliability) and the efficiency of their process to increase their profit, ultimately saving money for the taxpayer while improving support to the Warfighters." [10]

There are mutual benefits from PBL to government and its contractors. At the point of contract renewal, a new-cost basis is used to further reduce the cost to the federal government, allowing it to benefit from the improvements made by industry in product and process. Industry benefits by:

- Keeping the increased profits (either in whole or part) that come from lowering their cost to deliver.

- Stabilising their revenue stream with longer-term arrangements and by leveraging the government's facilities and workforce as against their own invested capital.

Bibliography

Performance Based Logistics (PBL) Metrics - Overview, AcquiPedia, DAU

Turning acquisition on its head, 1 January 2013, Armed Forces Journal

Modernizing Defense Logistics, 25 June 2009, Aerospace Industries Association

This paper is part of the following report: Defense Acquisition Review Journal. Volume 11, Number 3, December 2004-March 2005

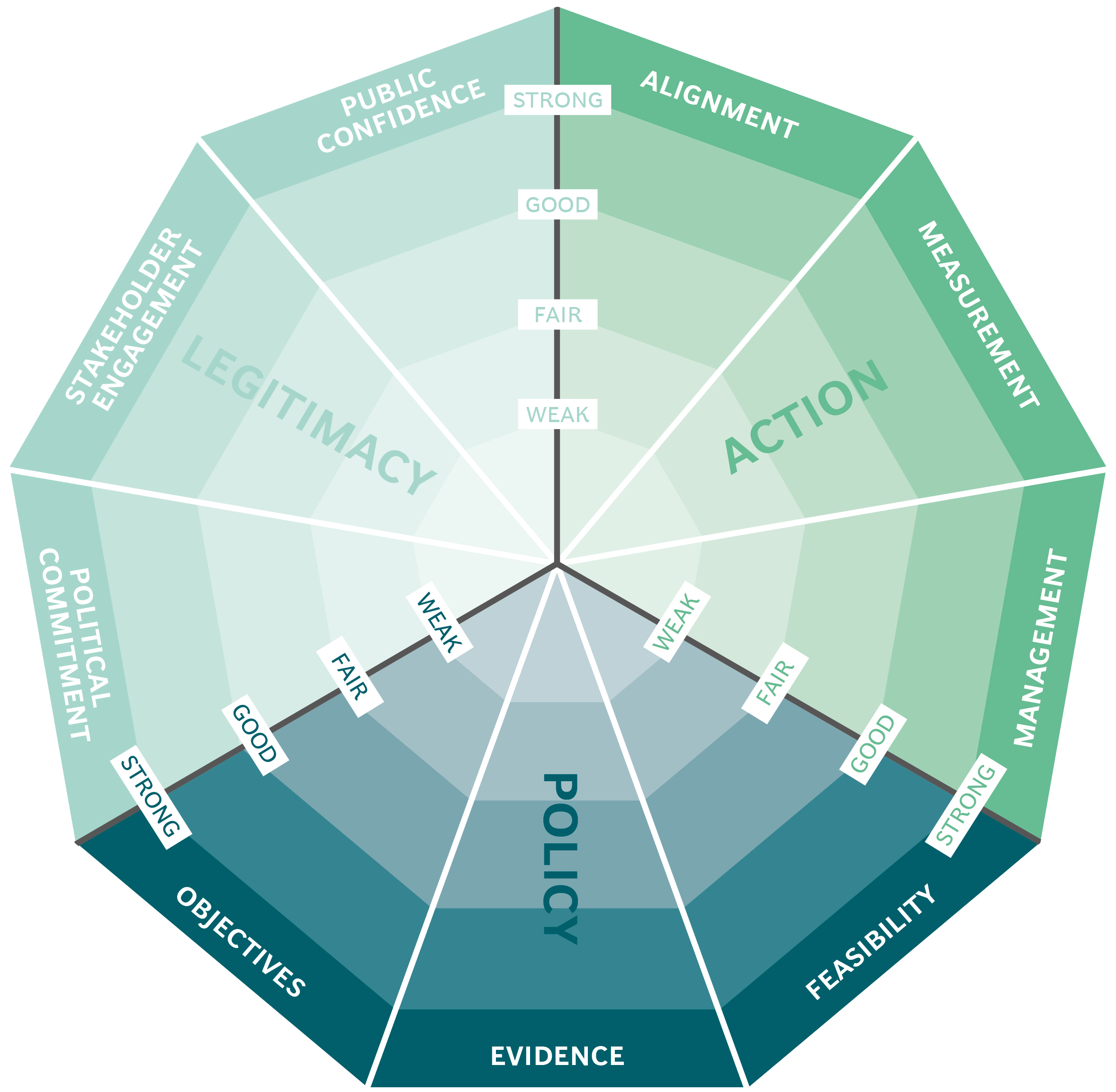

The Public Impact Fundamentals - A framework for successful policy

This case study has been assessed using the Public Impact Fundamentals, a simple framework and practical tool to help you assess your public policies and ensure the three fundamentals - Legitimacy, Policy and Action are embedded in them.

Learn more about the Fundamentals and how you can use them to access your own policies and initiatives.

You may also be interested in...

National portal for government services and Information: gob.mx

BANSEFI: promoting financial inclusion throughout Mexico

Formalising the appointment and compensation of Chile’s senior civil servants

The eco-friendly façade of the Manuel Gea González Hospital tower in Mexico City